Short grain

- Jeremy Broun

- Nov 1, 2024

- 4 min read

Updated: Jun 30, 2025

October 2024

Its been a while since I posted and probably no bad thing as there is so much opinion out there bombarding our senses daily. But I hope when I do write a blog I have something worthwhile to say, even if only a few people read it in this new wold of online woodworking gurus! Do people still read blogs?

An issue that cropped up during my judging of The Alan Peters Furniture Award this year (2024) and again in a video on Instagram is short grain and its inherent structural weakness.

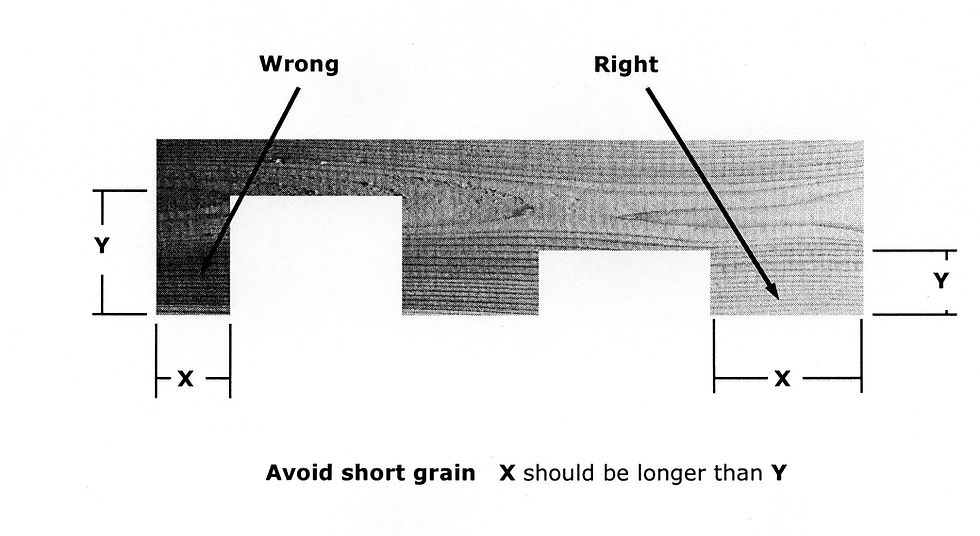

This diagagram demonstrates the X Y rule I taught back in my esarly days of school teaching. It is a very simple rule; X should be longer than Y in a construction.

Of course this was back in the last century when woodwork was taught in school. Fast forward to today and YouTube and Instagram is where most people learn woodwork. Certainly there are major iunfluencers in the USA and UK and a new mindset of cancelling history and re-inventing the wheel as books and magazines are no longer the stalwart of curated information. But Nature does not lie and wood has no interest in history or fashion but has its own truth.

The first instance that came to my notice (and the other judges of the Alan Peters Furniture Award) was a striking looking immaculately veneered table. It had cantilevered legs as in the schematic cross-section diagam below:

The leg acts as a lever and where it joins the top you can immediately see the short grain and where the main stress point is. Strong woodworking joints rely on long overlapping fibres. So these fibres are further weakened by the large wooden dowels that are presumably used to re-inforce the joint!

It reminds me of the antique chairs I used to repair in my early days as a furniture maker helping pay the workshop rent. The mortice and tenons had long since loosened by the detereorated fish glue and subsequent attempts to repair the chairs would be to insert steel screws or wooden dowels. This involved drilling through the joint weakening the fibres and further weakening the chair.

Below is a schematic sectional diagram of a beautifully crafted small table leg joint, video filmed on Instagram with mouth watering closeups of the joint being squeezed together and the dowel plug shaved flush with a chisel. So one presumes a steel screw has been inserted to strengthen the joint. Now this diagram is a cross section through the middle of the joint, whereas the table top female joint receives much of the short-grained cantilevered leg but the effect is the same. The strength of the joint is always at the weakest part.

I was not going to mention names but I did in fact engage in a friendly but critical conversation with the maker a rising star - Tom Addison. And of course he defended what he described to me as a 'controversial' joint by saying it had been thoroughly tested by him and his wife sitting on it. Reminds me of my radical cantilevered rocking chair design!

Anyone following my own furniture making career would know I was the first to challenge tradition and was quite a rebel, paying the price sometimes when I broke the rules and did not respect that timber moves. I am passionate about innovation but in the back of my mind I always ask - how will this piece of furniture be abused as well as used and will such a joint withstand a really sudden jolt or somebody standing on the table to change a lightbulb.

What came out of this risky taboo breaking convention of oine furniture maker not challenging another was a friendly off-topic exchange as I looked at Tom's website and discovered he was 2014 Fell running British champion so I spilled the beans on his Instagram feed that in my youth I won my school record for 440 yards at 51.3 seconds, clipping .6 of a second off the then Women's world record. But it was a meaningless story as I was nowhere near British male champion standard! I gained insight into the struggles of today's young makers, many ofg whom have young families to support,a stark choice I had to make as a young man that I could not earn enough as a designer maker to support a wife and kids.

Wood is a curious animal, sometimes we can get away with pushing the boundaries and sometimes with modern adhesives but the fundamental fibrous character of wood hasn't changed. If my half century of experience is worth a dime to anyone perhaps my suggestion would be don't re-inforce the joint, you are cutting into/severing essential fibres that give the joint strength. Using steel re-inforcing rods with epoxy glue should be controversial in that some very famous and very expensive chairs have featured this but what happens over time? Wood and metal have a different co-efficient of expansion. I am not going to mention this particular name but I will pass on what Alan Peters once said to me 'You would do well to visit a museum and see how wood behaves over time'.

Advice from those who came before.

Comments