Beginner's Guide to Custom Guitar Making

- Woodomain - Jeremy Broun

- Aug 11

- 1 min read

I suppose referring to the art of the luthier as custom guitar making is a bit like calling Quiche Lorraine ham and egg pie. Let's stick with the latter as it might have more purchase with the woodworking beginner wbo wants to build a guitar that he/she can play.

Purchase is a consideration as traditionally there are many specialist guitar building tools and jigs that are expensive. This is not to mention the variety of fancy woods in an acoustic guitar such as Balkan spruce for the top, mahogany or maple for the neck and the back and sides, rosewood or ebony for the fingerboard and bridge.

But you do not have to follow tradition to make a traditional guitar. Instead of steam bending the rosewood sides you can cold bend usingf a 2mm thick model making birch ply. You can use off the shelf prepared pine for the neck, laminating in strips to increase stability and you can purchase a pre-fretted fingerboard as that is probably the most skilful task involved. Selecting a good quality sound board (joined in two matching halves) can cost as little as "20 and the tools used can be basic lowcost woodwoodworking hand tools as well as a router costing under £60.

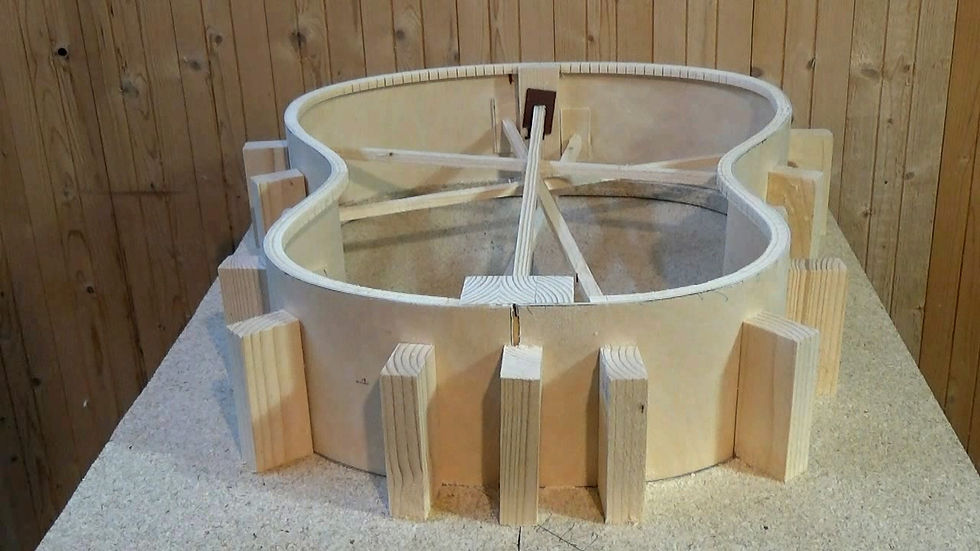

The basic guitar making jig to form the body can be made from a piece of chipboards and using the same prepared wood strip sources from B & Q or similar.

ccccc

Comments